Tee joint and lap joint welds are some of the most common welds performed by fabricators today. Both of these common welds, as well as all fillet welds, must be finished properly in order to hold their integrity.

Because fillet welds are structural, it is extremely important not to remove too much of the weld when finishing. Instead, the weld should be reshaped into a radius through blending. Failure to blend these welds compromises the rust proof properties of stainless steel and leaves an unfinished look on other metals. Blending also smoothes the weld, which is important for any surface that comes into contact with people (e.g. handrails, door handles, etc.)

Access is typically the number one issue when it comes to blending fillet welds. Using a die grinder with a type 1 wheel is often impossible; due to the angle the tool must be held. Right angle grinders frequently have the ability to access the weld, but standard type 27 products aren’t ideal for creating a radius. Standard depressed center wheels are rigid and can easily remove too much material. Flap discs can’t create the radius needed because only the face is constructed with usable abrasive material.

Specialized flap discs for fillet weld blending are on the market, but because they are flap discs, life is limited. This isn’t an ideal solution for fabricators that deal in volume or for shops interested in keeping equipment costs down.

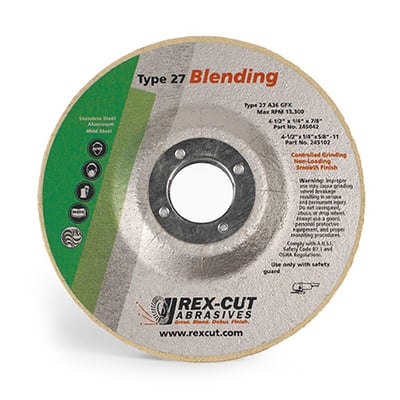

But, fabricators using Rex-Cut Type 27 Blending Wheels on right angle grinders have success blending this type of weld easily and economically. This versatile wheel offers four key advantages to make blending fillet welds a breeze:

- The Rex-Cut Type 27 Blending Wheel is easily shaped into a curved edge to fit any joint, giving you the perfect radius shape every time. Once dressed, the wheel will hold its shape and can be easily redressed to fit different sized joints or optimize its efficiency.

- Grain is embedded throughout the Rex-Cut Type 27 Blending Wheel, making it possible to use the face, edge, and top of the wheel for blending. The entire wheel is constructed of abrasive material, which helps finish welds faster and more evenly.

- Rex-Cut Type 27 Blending Wheels are renowned for the excellent and consistent surface finishes that they leave on welds. Fabricators using this wheel can be confident they will get the same finish each time they pick up the wheel.

- When it’s time to radius a weld, there’s no need to switch tools; the Rex-Cut Type 27 Blending Wheel can easily handle the job. Finishing fillet welds can be completed from start to finish using only this highly versatile wheel.

For even tighter spaces where right angle grinders can’t reach, we do make mounted points with the same abrasive material as our Type 27 Blending Wheels. These points, run on a die grinder, can even blend welds inside corners of handrails and tubing.

Keeping the structural integrity when finishing fillet welds is important, so is keeping your abrasive budget under control. Users of Rex-Cut Type 27 Blending Wheels know they are using the best tool for the job that makes no concessions when it comes to results.

If you want to finish fillet welds using one tool that will outlast other abrasives, check out the Rex-Cut Type 27 Blending Wheel today.

To see if this wheel will work for your application, email your application details and questions to products@rexcut.com.