Rex-Cut Abrasives are trusted by metal fabricators across the country to reduce labor time and improve surface quality. Our unique resin-bonded cotton fiber abrasives "combine grinding and finishing power in a single product, improving productivity without sacrificing precision.

High-performance wheels designed for rapid metal removal, weld preparation, and aggressive grinding without excessive heat.

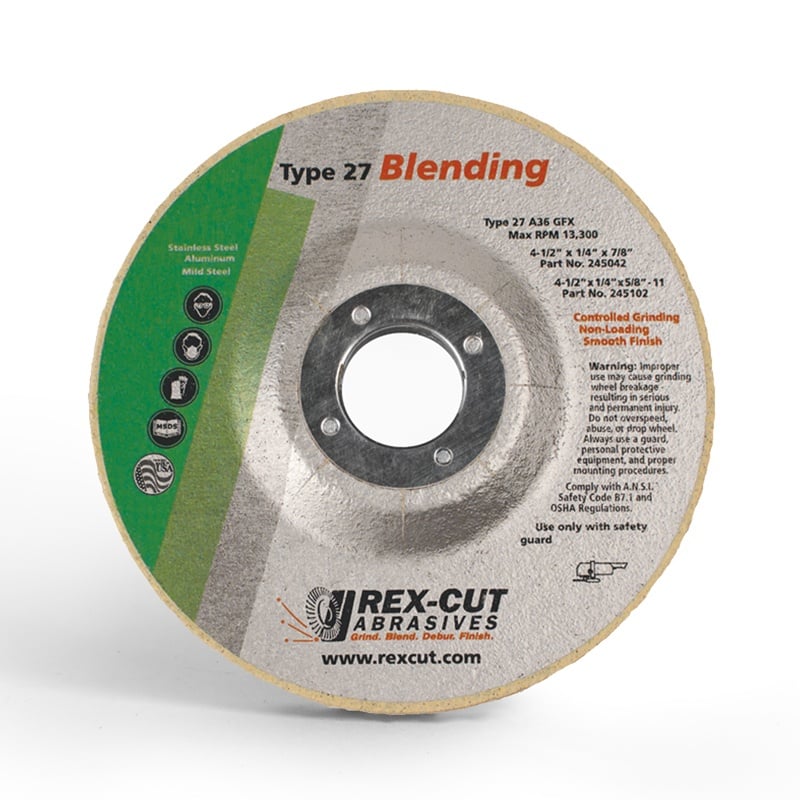

Rex-Cut Type 27 grinding wheels are manufactured with our signature cotton fiber abrasive materials designed for grinding and blending in one step.

Rex-Cut’s MegaBrite T27 Unitized Discs are manufactured at our plant in Fall River, MA by combining non-woven nylon, resin, and aluminum oxide or silicon carbide grain. Layers of this material are then pressed and mounted onto fiberglass backings. These discs are ideal for deburring, blending, and finishing.

Excessive time spent switching between cutting and finishing tools

Cotton fiber abrasives cut and finish in one step, reducing tool changes and process time.

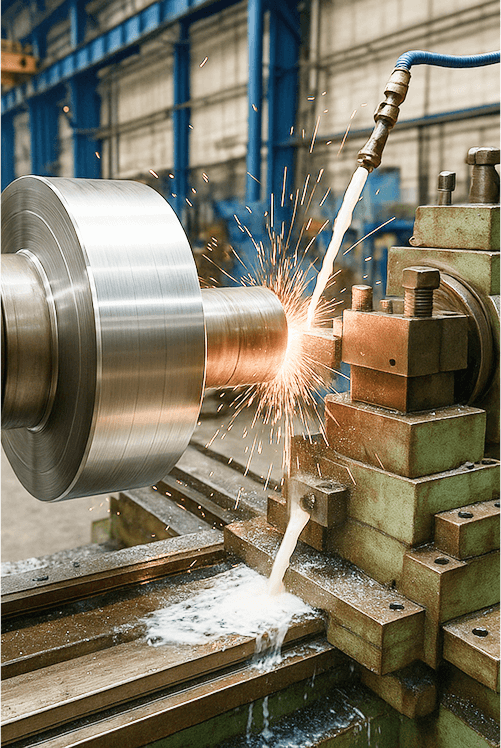

Heat discoloration and warping during grinding

Rex-Cut wheels grind cool, minimizing heat buildup and protecting metal integrity.

Inconsistent finishes across parts

Our abrasives offer controlled, repeatable performance for a uniform finish.

Short wheel life and frequent replacements

Durable cotton fiber and unitized wheels last longer and maintain performance over time.

Difficulty accessing small or complex part geometries

Cotton Fiber Points are designed to reach tight spaces without compromising control.

Blog Post

Blog Post

Blog Post

Blog Post

Blog Post

Blog Post

Blog Post

Blog Post

Video

Video

© 2025. Rex-Cut Abrasives.

All Rights Reserved.

960 Airport Road

Fall River, MA 02720

Phone: (800) 225-8182

Fax: (800) 638-8501