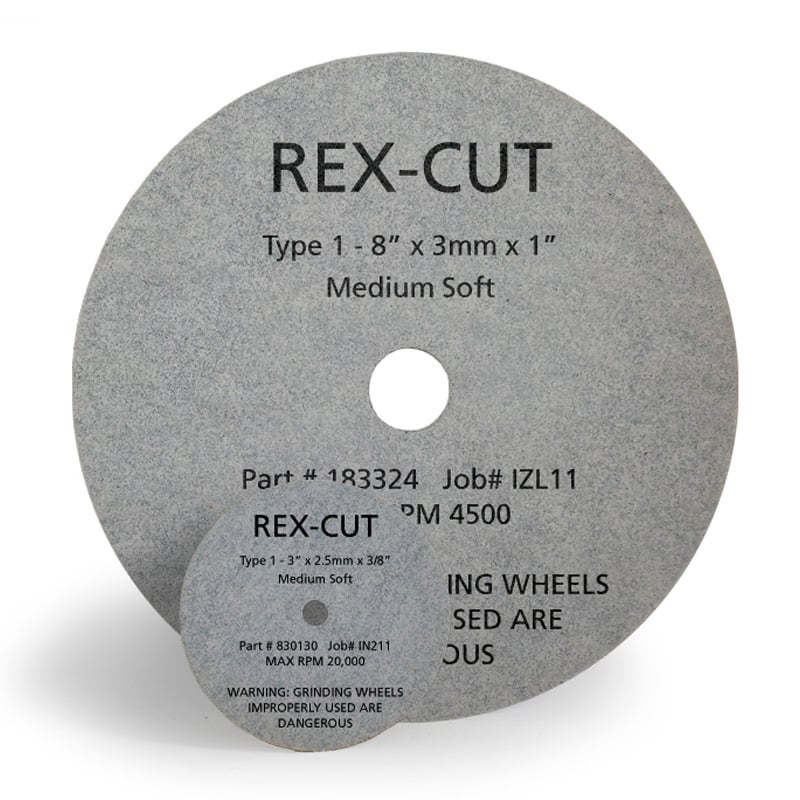

Rex-Cut Type 1 Laser Braze Finishing Wheels have been engineered to finish brazing in roof joints for automotive assembly.

High-performance non-woven wheels for light deburring, blending, and surface finishing on stainless steel and other metals. Ideal for achieving a consistent, satin finish.

Precise finishing requirements

Abrasives engineered for automotive surface standards

High productivity demands

Multi-functional abrasives increase throughput

Surface integrity

Solutions designed to protect critical automotive materials

Blog Post

Blog Post

Blog Post

Blog Post

Blog Post

Blog Post

Blog Post

Blog Post

Video

Video

© 2025. Rex-Cut Abrasives.

All Rights Reserved.

960 Airport Road

Fall River, MA 02720

Phone: (800) 225-8182

Fax: (800) 638-8501