At Rex-Cut, we’ve spent over 90 years developing abrasive products that meet the real demands of metalworking professionals. Whether you're cutting, grinding, deburring, or finishing, our abrasives are built to help you get the job done right—with fewer steps, less downtime, and better results.

We offer a complete selection of abrasives designed to perform across materials, applications, and industries.

Meet MegaBrite:

Built for demanding finishing applications, MegaBrite unitized wheels offer:

Tight control over cut and finish – ideal for tight tolerances

Application-specific options – multiple densities and grits

Reduced operator fatigue – easier handling with less effort required.

Less rework, fewer passes – finish right the first time

Get the right product for your metal, finish, and setup—no guesswork.

95+ Years of Experience

Made in the USA

Thousands of Successful Applications

Responsive technical support and application guidance

Built to reduce steps and deliver consistent results

Matched to your metal, process, and performance needs

Custom Solutions Available

“While choosing an abrasive to use in a robotic deburring cell to finish the edge of a turbine blade, the Smooth Touch wheel outperformed non-woven nylon wheels significantly. It was able to obtain the desired finish without changing the part geometry as measured by a laser sensor.”

Robotic Finishing Expert at AV&R Vision & Robotics

"The material removing capabilities of Sigma Green has cut down expenses by at least 50% due to the longevity of the product. But the biggest thing is frustration factor. I’m less fatigue at the end of the day, I spend less time changing out equipment, and I’m protecting my health."

Metal Designs

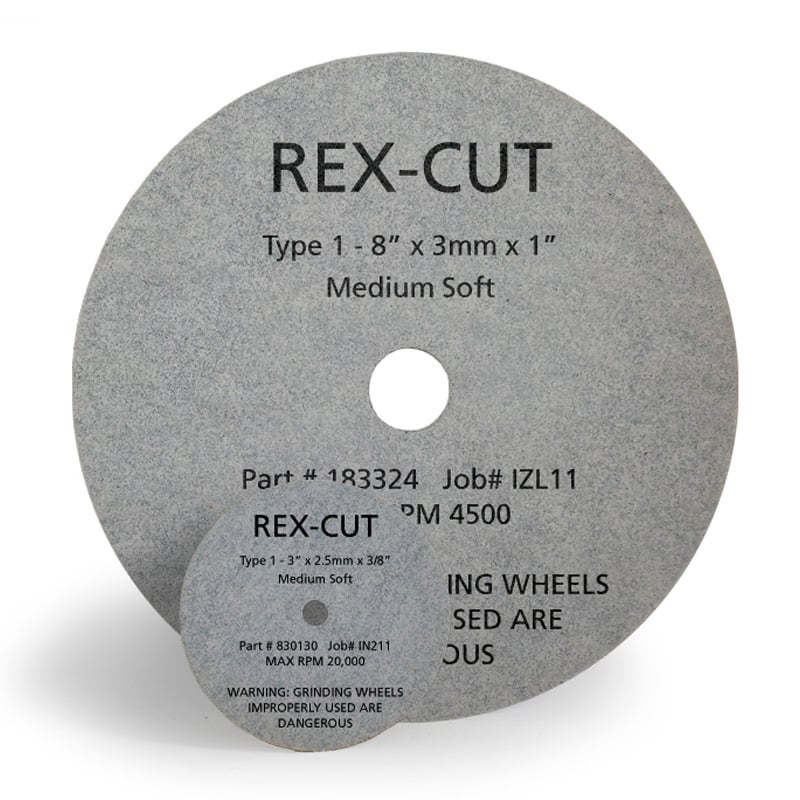

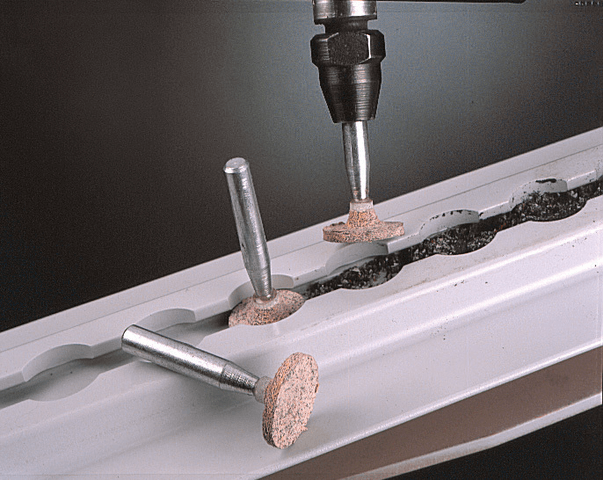

"Implementing the Rex-Cut Type 1 Braze Finishing Wheel at our plant to finish roof seams yielded direct results in both increased productivity and the quality of weld finish. This change has led to significant cost savings for the production of Ibiza, our best-selling car."

Engineer at SEAT, a part of the Volkswagen Group in Spain

Rex-Cut abrasives are engineered to last longer, perform faster, and reduce rework—helping you lower your total cost per finished part.

“Our mission is to provide high-performance abrasives with a focus on efficiency, cost savings, safety, and fast delivery to all our valued customers.”

Bob Costa

President

© 2025. Rex-Cut Abrasives.

All Rights Reserved.

960 Airport Road

Fall River, MA 02720

Phone: (800) 225-8182

Fax: (800) 638-8501