INTRODUCTION:

Shipbuilders engage in practically constant welding and grinding while maintaining ships that are often several decades old. In fact, the shipbuilding industry probably does more welding and grinding than almost any other enterprise. With plates that are 4-5 inches thick or more, removing welds and rust from these ships requires a durable abrasive wheel. But when selecting a wheel, you must consider more than durability or you risk using a product that is slower at removing material, has a poor-quality finish—and most importantly—could risk the health of operators.

When durability is the only concern, shipbuilders might select a thicker, coarse product with a harder abrasive bond to maximize wheel life. But this type of wheel has several problems including:- A sub-par finish, requiring extra grinding cycles to achieve acceptable standards

- Longer time required to remove the same amount of material

- Significantly higher levels of vibration, which can directly impact anyone using the wheel

The last issue is one of serious concern. Wheel vibration is responsible for Hand/Arm Vibration Syndrome, a serious neurological and circulatory condition, identified by numbness and pain in the fingers, with the fingers actually changing color in severe circumstances. Since this is a cumulative impairment, it may worsen to the point where an operator could actually lose fingers. This condition is serious enough that the European Union has started regulating wheel usage and the Occupational Health and Safety Administration (OSHA) is now looking at mitigating hand/arm vibration syndrome in the U.S.

Even without the immediate threat of OSHA regulations, shipbuilders that do not take steps to reduce operator exposure to excess vibration can face lost production time, increased sick outs, worker compensation claims, and litigation.

FINDING THE RIGHT BALANCE IN SHIPBUILDING:

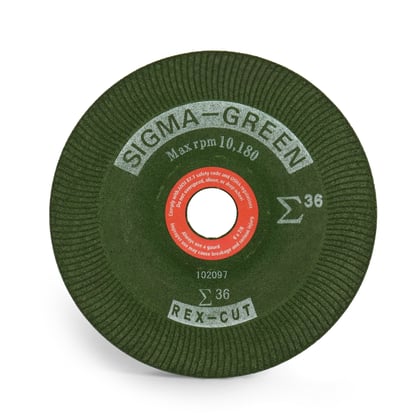

When evaluating wheel selection options in shipbuilding, rate of material removal, finish quality, low vibration and durability must be balanced to maximize operator safety and performance. That’s why Rex-Cut developed the Sigma Green wheels, to ensure that a grinding wheel does not become a “one trick pony.”

A standard Sigma Green Wheel has superior material removal and produces a quality finish from a 3/16” wheel. By dropping some of the thickness, the result is a low vibration, durable wheel that reduces the chance of repetitive stress injury for the operator.

Low vibration wheels can also reduce maintenance costs on grinding equipment. Grinder manufacturer Metabo found that by controlling vibration, its grinders lasted 50-100% longer before requiring maintenance. Carbon brush replacement time doubled from 100 to 200 hours, and common replaceable components such as ball bearings and winding also increased in longevity.

OTHER SHIPBUILDING CONSIDERATIONS:

There are a few other things to think about when deploying an abrasive wheel in shipbuilding. With the high level of aluminum used in ship construction, an added benefit of Sigma Green wheels is that they can be used on aluminum without requiring the addition of waxes or other lubricants. We’ve even discovered that customers are using our wheels underwater: Divers are performing underwater welds and using the Sigma Green to grind down material while submerged.

When choosing a wheel, the product that simply lasts the longest is not necessarily the best. A wheel must ensure efficient operations and protect its operator to be effective. If durability is of utmost concern, Rex-Cut does offer the Sigma Green Max wheel. This thicker wheel will offer even more robust durability while only slightly increasing vibration.

Smart shipbuilders weigh the tradeoffs between durability and vibration, and tough, well-rounded abrasive wheels typically offers the most value to the shipbuilding business.

MORE ABOUT SIGMA GREEN:

To see how fast Sigma Green can cut, watch our demo video here.