How the Right Deburring Wheels Can Save Money and Help Protect the Environment

When manufacturing new pipe, joints must seal cleanly. Any excess material, known as a burr, can destabilize the integrity of the joint by creating gaps, resulting in leaks or other pipe failures. The liability of drilling mud or hydrocarbons seeping into the surrounding environment puts millions at risk. If a piece of burred pipe goes out to the rig, hours can be lost when a faulty pipe is discovered and must be corrected. Production delays in this type of environment can run into the tens of thousands of dollars—for the delay of a single hour. This makes the process of removing excess material, known as deburring, a critical component for successful operations on any oil rig.

THE RIGHT PROCESS TO DEBUR PIPE

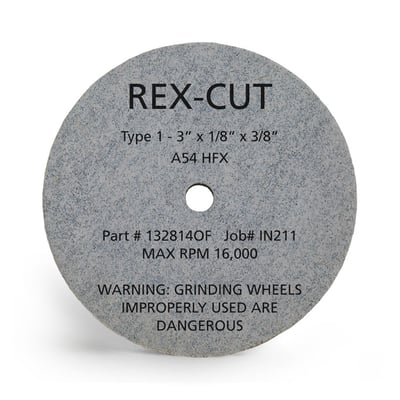

Type 1 Wheels are used to remove the excess material and ensure a successful pipe connection. To maximize the effectiveness of the wheel, we recommend placing a diamond file in a vice, then pressing the edge of the wheel to it at an angle. Run the wheel until an angled shape is formed. Repeat this process on the other side of the wheel and the final result will be a “v” shape. This shape will enhance the removal performance of the wheel as it fits down into the groove of the pipe thread. Click here for a video tutorial.

WHEEL SELECTION; CRITICAL TO SUCCESS

Typical deburring wheels are made from non-woven nylon. Non-woven nylon consists of an open nylon filament web that has an abrasive grain mounted to it using a bonding agent. The problem with these types of wheels is that you cannot shape them to match pipe threads as described above. This is due to the fact that non-woven nylon is simply not dense enough to be the most effective material in a deburring oil pipe application. Another issue is that non-woven nylon wears out relatively quickly.

We recommend a non-woven cotton fiber that’s more dense than non-woven nylon. It’s the type of material used in Rex-Cut wheels and it’s why Rex-Cut products last longer as well as perform with greater efficiency.

Non-woven cotton fiber wheels result in faster overall production time. Their durability shrinks delays, reduces overhead from using less wheels, and protects pipeline systems.